At Mining Wearhouse, we specialise in providing premium quality seal solutions for the mining industry. Our range of shaft seal methods for slurry pumps ensures optimal performance and extended service life, even in the most challenging mining conditions.

Types of Shaft Seals

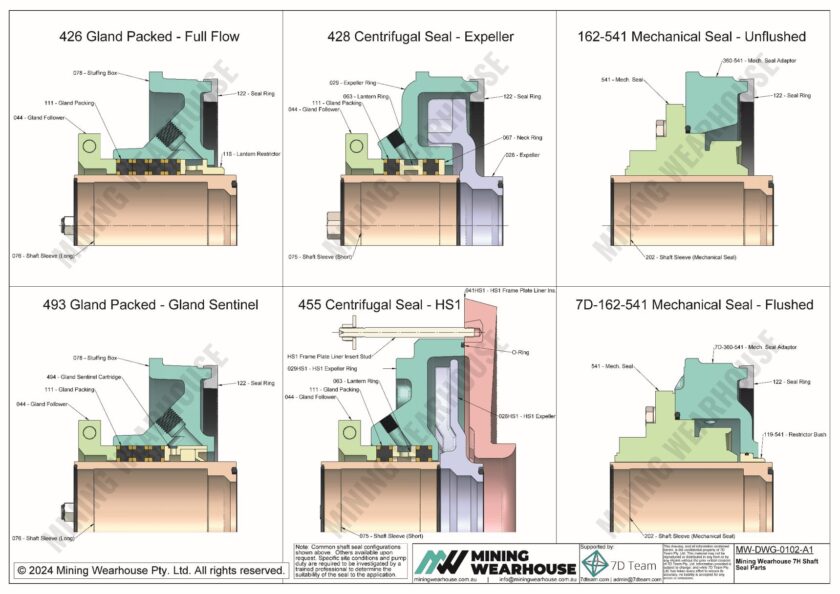

- Gland Packed Seals: Traditional and reliable, gland packed seals offer cost-effectiveness and are suitable for a wide range of applications. Our advanced gland packing materials reduce maintenance needs and enhance durability.

- Expeller Seals: Ideal for conditions where external flush water is unavailable, expeller seals utilise centrifugal force to prevent slurry leakage, reducing the need for maintenance and operational costs in constant speed services with low suction pressures.

- Mechanical Seals: When dealing with toxic or abrasive slurries, mechanical seals provide the best leakage protection. Our mechanical seals are engineered to withstand high pressures and abrasive materials, ensuring minimal downtime and maintenance.

Optimising Your Pump Performance

Choosing the right shaft seal is crucial for optimising the performance and longevity of your pumps. Our team at Mining Wearhouse, and our team of well trained and audited Distribution Partners, can help you select the most suitable seal type based on your specific operational requirements and environmental conditions.

For more information on our shaft seal solutions and to ensure your pumps operate at peak efficiency, contact our technical support team.